Is there any reason that little silver part of the extruder wouldn’t move and start clicking while printing when printing at 205 in PLA. It seems to turn just fine without any filament in there otherwise.

I cleaned out a nozzle clog, but is it possible there’s junk in the hot end stuck?

Resolution: Thanks for your help everyone! It ended up being a nozzle clog that I didn’t get all the way out. I ended up heating the printer up and doing the cool down trick. That seemed to work as a last ditch effort before buying a new nozzle.

Could be too much pressure – double check your z-offset/leveling? I had it so bad, and didn’t realize it, … and wore out the original brass gear :(. The nozzle was pushed right up against the bed, so it was trying so hard to push out filament that wasn’t going anywhere.

I just test, unfortunately it looks like thats not the issue. But that raises the question, could the spring tension be to high?

in my case it was too cold. My HE doesn’t work very well and every time this happens is because it’s not heating enough

try upping the temp and try again, see if works

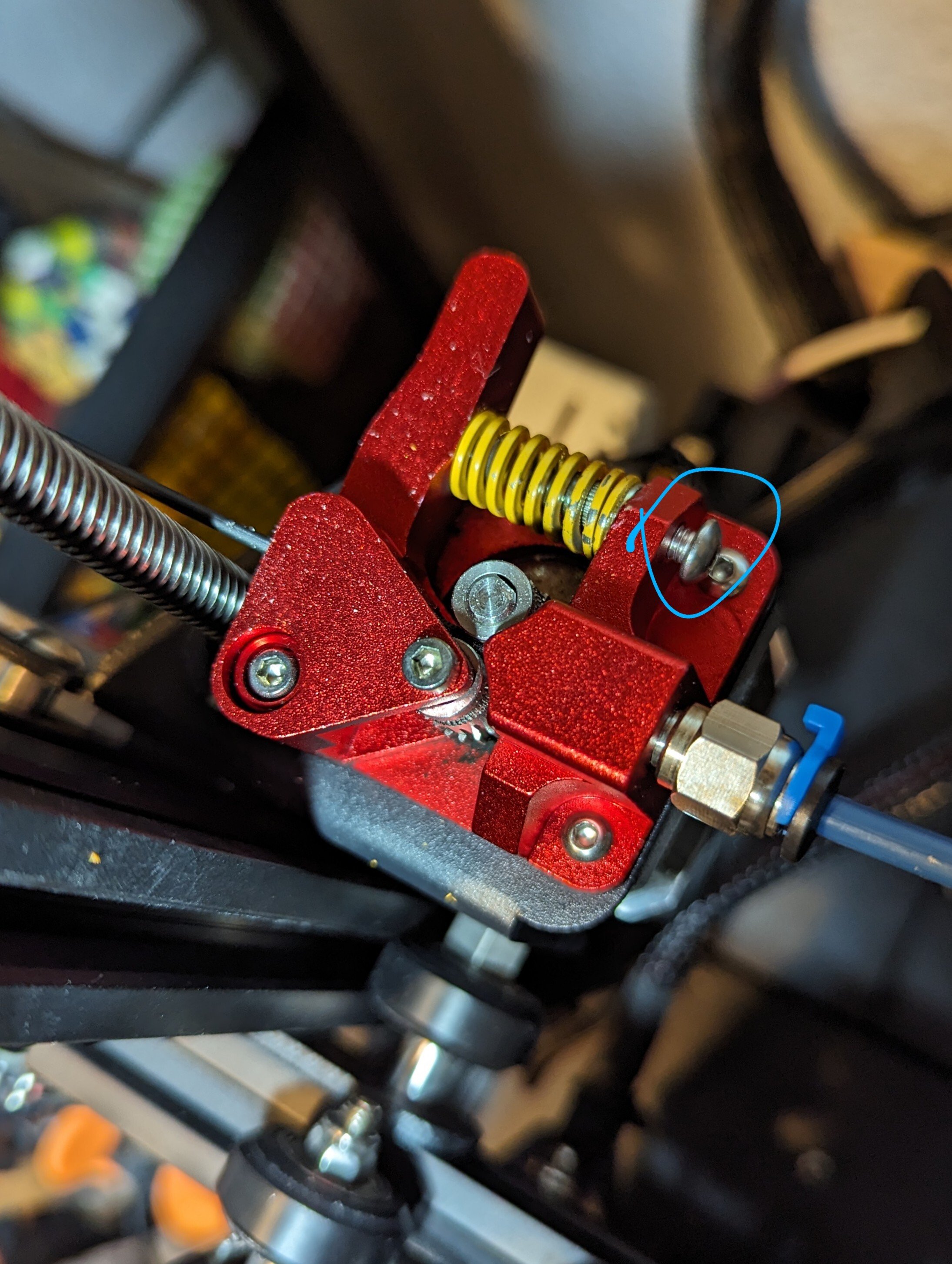

Check the screw that is imbedded in the brass gear. It holds it in place to the stepper motor it is attached to. If it is loose at all then it will produce similar results to a clog. Also be sure that the screw is aligned to the cutout on the stepper motor axel. That is what keeps it spinning. If it is tightened but not aligned then it will make that skipping sound.

Thank you! I retested and tighten the screw down way more. I’m testing now. Fingers crossed that did it

One more thing to check that caused clicking on my ender 3, the plastic retention arm the spring connects to had busted. I couldn’t even tell because it was underneath the silver roller.

They make a kit for $12 on Amazon that exchanges the plastic parts for aluminum parts because apparently this failure is almost guaranteed to happen eventually.

https://youtu.be/YakBCTKhX3c This guy’s choice of fashion may be questionable, but he’s spot on on the problem in this video.

Here is an alternative Piped link(s):

https://piped.video/YakBCTKhX3c

Piped is a privacy-respecting open-source alternative frontend to YouTube.

I’m open-source; check me out at GitHub.

Your plastic is jammed. I think the clicking sound is from the extruder moving, but since the plastic is stuck, it compresses a mil or two before springing back and compressing again.

Your jam might be in the hot end. Heat it up really hot, pull the plastic out, and clear the nozzle with a fine metal pin. If that doesn’t fix it, you might need to replace the nozzle and reseat the bowden tube against the nozzle, making sure the end of the tube is cut very straight and perpendicular.

Hope that helps! This happens to me too from time to time.

It looks like I can’t extrude in the air either. Maybe I didn’t get all the gunk out of the nozzle the first time I’m just clueless on how to. I tried soaking it and acetone and digging stuff out and that didn’t seem to do it and the only pen I have doesn’t go through the hole in the nozzle. It’s too thick. It’s sitting at about 240 right now so I’m hoping That it just melts I guess.

At this point, I’m wondering if it’s not just worth buying a new nozzle and calling it a day

Heat the nozzle up to like 215C and then shut it off. Wait for the nozzle temp to reach 90C and then yank the filament back out. If you do it correctly, the very tip of the filament you yanked out should be a fine cone shaped point. This is referred to as a cold pull.

It is not really worth it trying to clean a clogged nozzle. Just toss it and replace it.

99% of the time, it’s a clogged nozzle. Do a routine clean and check if you can extrude while in the air. Check e steps.

Like others are saying, probably a clogged nozzle. However, I want to say I just went through this myself and it was not a clogged nozzle. At temperature, I could put light pressure on the filament with my hand and it would come out smoothly, no clog. It can also be that your nozzle is too close to the print bed. In my case, it would do this even when suspended in the air, so that was not the issue.

I upgraded to a metal extruder, and no longer have this issue.

Despite what most people say, sometimes parts are the problem. This other commenter explained better.

You might have had a bad stepper motor on the extruder. I recently went through this whole issue and after trying all the usual suspects, determined that a bunch of filament flakes/dust had found its way into the extruder stepper which would cause it to lock up intermittently.

I’m still using the same stepper motor, but that was next on my list had replacing the extruder not solved the issue.

deleted by creator

My dad has an ender 3 which occasionally does this. I haven’t been able to find anything regarding the problem. Could you elaborate on this hot end fix?

Is this it? https://www.thingiverse.com/thing:3203831

deleted by creator

What’s that?

Can you remove the extruder side of the Bowden tube so the extruder would just push filament through the tube and not any of the hot end? If this works you’ve got something up with the hir ene. If it doesn’t, move closer to the extruder motor.

deleted by creator

Literally just had this issue. Try loosening the screw on the extruder spring. That fixed it for me.